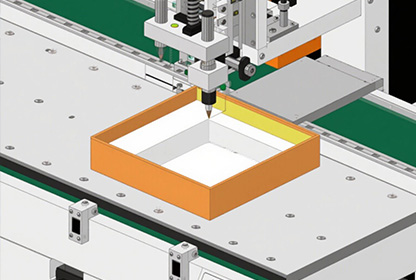

Modern automatic box packaging machine is equipped with intelligent control system, which is operated and monitored through touch screen or other human-machine interface. Intelligent control system can monitor the status of the equipment in real time, deal with abnormalities in a timely manner, and improve the stability and reliability of the equipment.

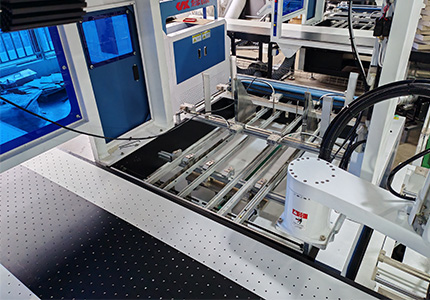

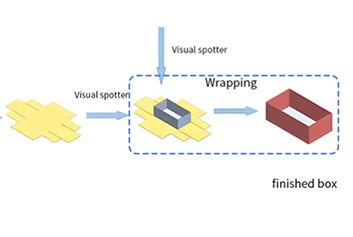

Fully automatic visual positioning is installed on the production line. Through the machine vision positioning system, the machine can automatically identify and grasp the parts to be processed, avoiding the errors and low efficiency problems in traditional manual operations. At the same time, the system can monitor various links in the production process in real time, ensuring the efficient operation of the production process. This not only improves production efficiency, but also reduces production costs, bringing considerable economic benefits to the enterprise. At the same time, the visual positioning system can also be transplanted onto existing or old mobile conveyor belts, with flexibility.

The visual system has deviation optimization, even if there is a slight deviation of the paper on the glue, the system will directly correct the position, with a tracking accuracy error of ± 0.2mm.

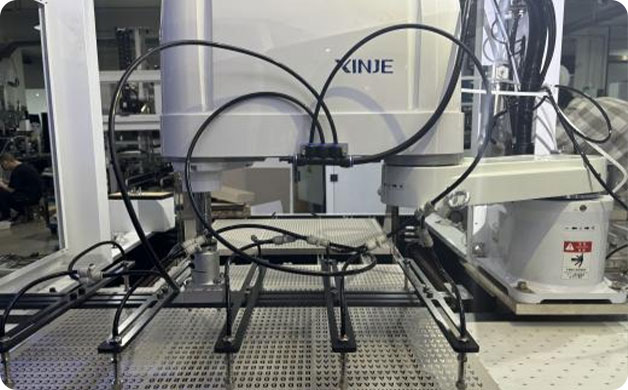

Mechanical arm

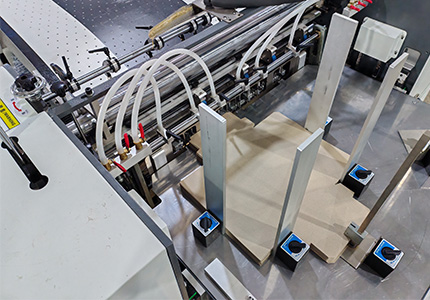

Firstly, the robotic arm has strong flexibility and can adapt to various complex task requirements. The robotic arm adopts advanced servo motors and motion control systems, which can achieve high-speed and high-precision motion control, and quickly and accurately complete a series of actions such as grasping, handling, and stacking.

Secondly, the robotic arm is equipped with various sensors and advanced visual recognition technology, which can achieve precise perception and positioning, quickly identify items of different shapes, sizes, and colors, and automatically classify and stack them. The product adopts intelligent PLC touch screen control, and users can monitor and adjust the robot in real time through the intelligent control panel or remote control system, with simple and convenient operation

In addition, the safety of the robotic arm is high, equipped with various safety devices and sensors, which can achieve safe operation and reduce safety risks for workers. High degree of automation, able to integrate with various automation equipment and systems, realizing the components of automated production lines, improving production efficiency and reducing labor costs.

Positioning System (Box Silo/Cot Silo Can be independently transplanted)

Download

Download