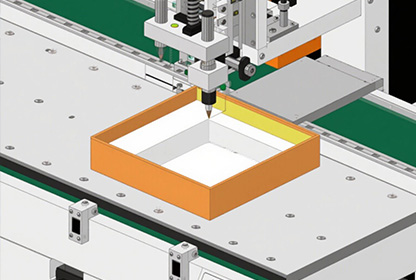

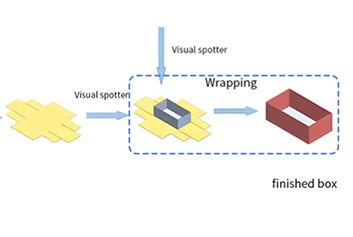

In the fields of industrial automation and precision manufacturing, automatic visual positioning technology can achieve micrometer level positioning accuracy and efficient part alignment and bonding, greatly improving production efficiency and product quality.

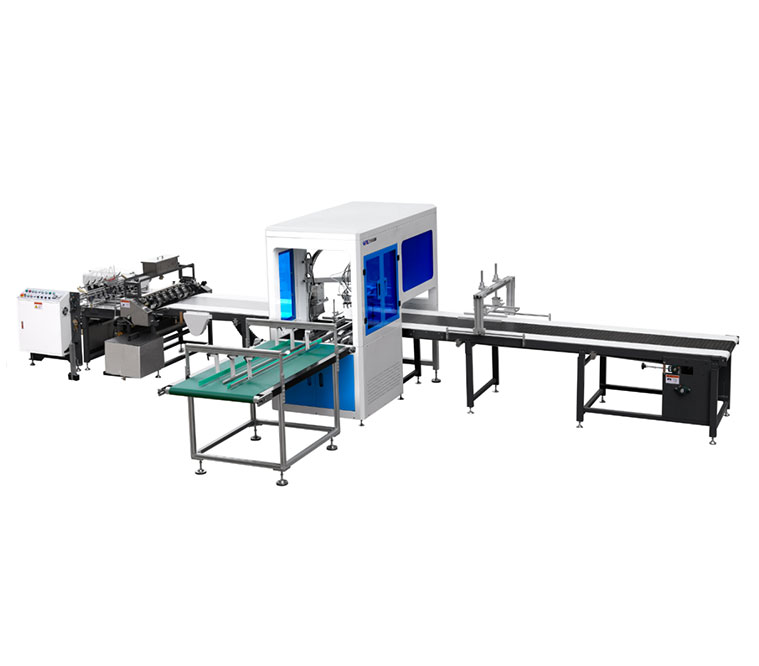

The difference from the previous model is that the HS700 meets the needs of users who only need to make sky and earth covers or have larger product box sizes, and requires a fully automatic sky and earth cover device to solve the current needs. Having high cost-effectiveness, it reduces equipment procurement costs for customers.

The automatic visual positioning machine measures items through scanning, avoiding potential secondary damage hazards caused by contact measurement and improving the reliability of the system.

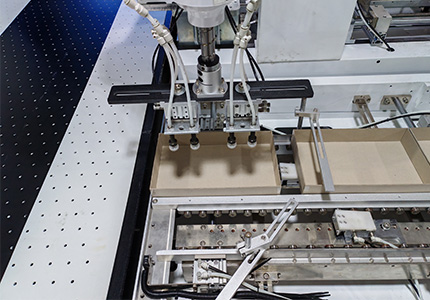

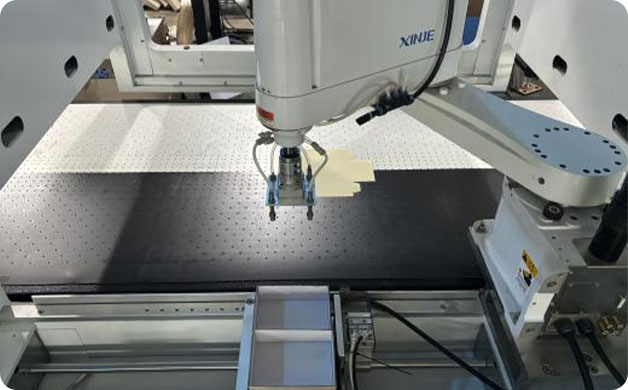

Mechanical arm

The robotic arm has strong flexibility and can adapt to various complex task requirements. The robotic arm adopts advanced servo motors and motion control systems, which can achieve high-speed and high-precision motion control, and quickly and accurately complete a series of actions such as grasping, handling, and stacking.

Secondly, the robotic arm is equipped with various sensors and advanced visual recognition technology, which can achieve precise perception and positioning, quickly identify items of different shapes, sizes, and colors, and automatically classify and stack them. The product adopts intelligent PLC touch screen control, and users can monitor and adjust the robot in real time through the intelligent control panel or remote control system, with simple and convenient operation

In addition, the safety of the robotic arm is high, equipped with various safety devices and sensors, which can achieve safe operation and reduce safety risks for workers. High degree of automation, able to integrate with various automation equipment and systems, realizing the components of automated production lines, improving production efficiency and reducing labor costs.

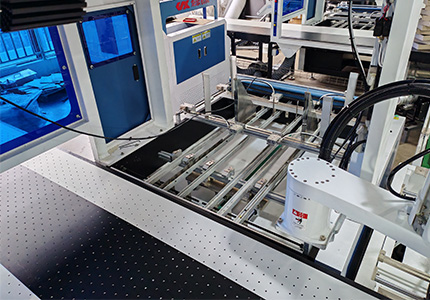

Positioning System (Box Silo Can be independently transplanted)

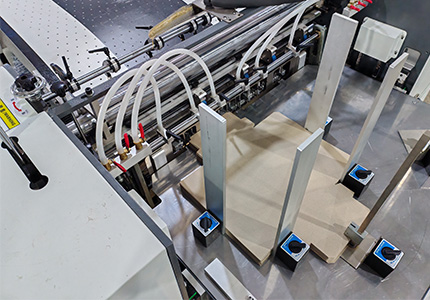

Industrial cameras can capture dozens to hundreds of images per second, much higher than ordinary cameras.

The shutter speed of industrial cameras is very fast, which can capture high-speed moving objects clearly.

Industrial cameras output raw data with a wide spectral range, suitable for high-quality image processing algorithms such as machine vision applications

Download

Download