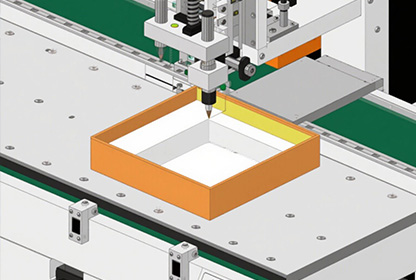

The advent of the bubble press machine solves the problem that the traditional manual scraping and rubbing is slow, labor-intensive and costly, and has rough precision. The use of the bubble press machine ensures that the paper box has excellent characteristics and precision after forming.

The use of the bubble press machine ensures that the paper box has excellent characteristics and precision after forming.

1. The bubble press machine has stable forming quality and fast bonding speed.

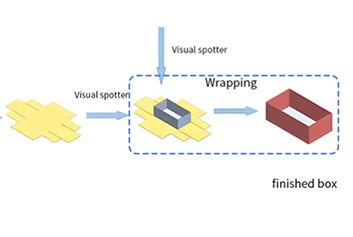

2. The machine has a simple structure and is easy to operate. Ordinary workers can quickly get started with production.

3. Compared with traditional manual labor, the bubble press machine has a fast production speed (generally 10 times the speed of manual bonding).

4. The bubble press machine is flexible in application. It can be produced by a single machine or configured with an assembly line for large-scale rapid production.

Download

Download