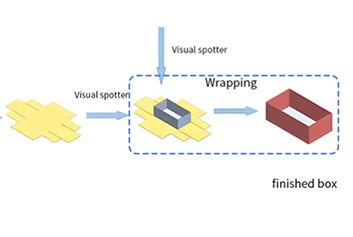

The double-station press machine is designed with two working positions, and each position can complete the press operation independently. When one station is performing the press operation, the other station can load or unload materials at the same time, thus realizing the continuous operation of the production line. This design not only reduces the idle time of the equipment, but also makes the production process smoother and effectively improves production efficiency.

1. High efficiency: The double-station design enables the press machine to work continuously, greatly improving production efficiency.

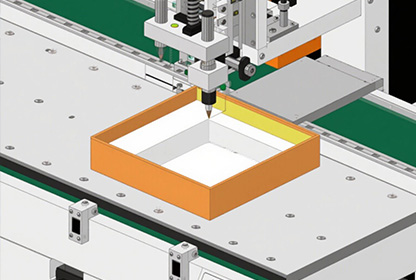

2. High precision: The double-station press machine usually adopts an advanced control system to ensure the accuracy and quality of the press.

3. Flexibility: The double-station press machine can adapt to products of different specifications and sizes, and has strong versatility and flexibility.

4. Easy maintenance: The equipment structure is reasonably designed, which is convenient for daily maintenance and maintenance.

Download

Download