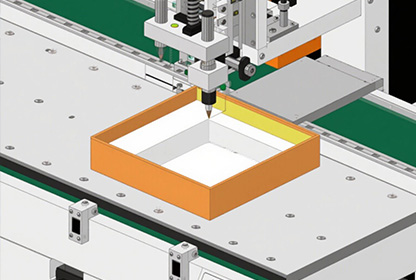

The cardboard slitting machine adopts advanced control system and high-quality cutting knives, which can ensure the precision required for each slitting and guarantee the product quality. Through the precise control system, the cutting accuracy can be controlled within 0.1mm.

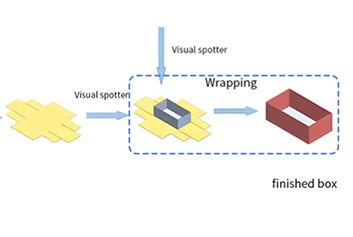

High Efficiency And Automation: The cardboard slitting machine adopts advanced cutting technology and optimized mechanical structure, which can realize fast and continuous slitting operation and significantly improve production efficiency. At the same time, it has the functions of automatic feeding, automatic cutting and automatic collecting, which reduces manual intervention and error, and lowers labor cost.

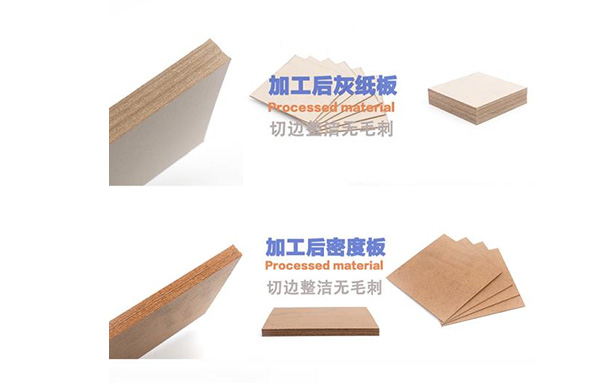

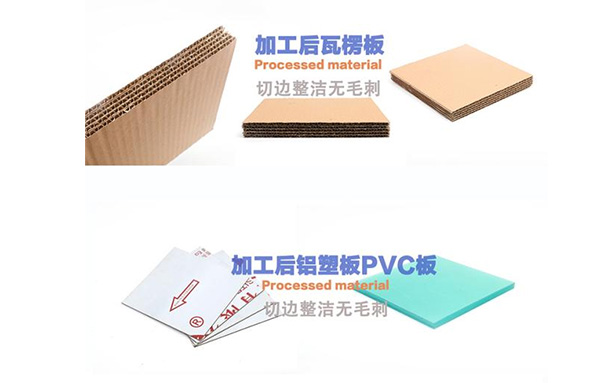

Strong adaptability: the cardboard slitting machine is suitable for slitting a variety of materials, such as gray board. It can also adjust the cutting size and speed according to different production requirements, with strong adaptability and flexibility.

Easy to operate: Cardboard slitting machines are usually equipped with a touch screen control panel with a user-friendly interface for easy setup and monitoring. In addition, some of the equipment also has an automatic counting device, which can show the production situation at a glance.

Maintenance: cardboard slitting machine maintenance is relatively simple, usually equipped with a vacuum device to keep the fabric and track clean, to extend the service life of the equipment.

Application areas of cardboard slitting machine: cardboard slitting machine is widely used in packaging, printing, metal processing and other industries. In the packaging industry, cardboard slitting machines are used to cut packaging materials into the required width and length to meet the packaging needs of different products. In the printing industry, cardboard slitting machines are used to cut large format prints into standard sizes for subsequent binding and processing.

Download

Download