Enhancing Precision in Box Making: The Role of Visual Positioning Equipment in Lid and Base Production

Apr 07,2025

Apr 07,2025In the world of packaging, precision and accuracy are crucial for creating high-quality products that meet both aesthetic and functional requirements. One of the most innovative technologies improving the precision in box making, particularly for Rigid Box style packaging, is the Visual Positioning Equipment.

This specialized machine is designed to offer superior alignment and placement of materials during the production of Rigid Box packaging, which consists of a separate lid and base. Whether it's for luxury packaging, gift boxes, or electronics, achieving perfect alignment during production is essential for ensuring the overall quality and durability of the product.

What is Visual Positioning Equipment?

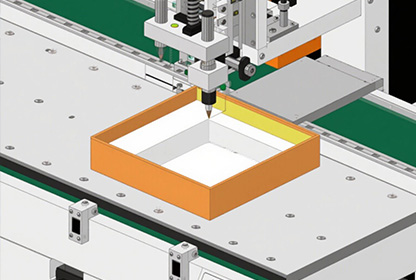

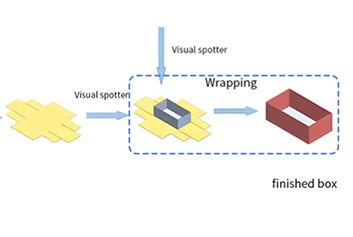

Visual Positioning machine utilizes high-definition cameras and advanced software algorithms to detect and correct any misalignments in real-time during the production process. In the context of Rigid box production, this machine helps to position the printed and cut materials precisely, ensuring that the lid and base align perfectly during the assembly process.

The core of this technology lies in its ability to “see” the product's components and compare them to predetermined parameters. If there’s any deviation from the expected position, the system automatically adjusts the positioning, ensuring that the lid and base come together seamlessly. This automation minimizes human error and enhances production efficiency, making the process faster and more reliable.

Key Features of Visual Positioning Equipment in Box Making

1.Precision Alignment: Visual Positioning Equipment ensures that each lid and base align flawlessly, regardless of the complexity or size of the packaging design. The ability to detect minute differences in position allows for greater accuracy during the manufacturing process.

2. Real-Time Adjustments: The real-time feedback and adjustment system means that the machine can make on-the-fly corrections, ensuring a consistent and high-quality output without the need for manual intervention. This feature is particularly useful in large-scale production runs, where consistent quality is paramount.

3. Increased Efficiency: By automating the alignment process, Visual Positioning Equipment significantly reduces the time spent on manual adjustments and rework. This leads to faster production cycles and an overall increase in manufacturing efficiency.

4. Improved Product Quality: With enhanced precision, the risk of defects such as misaligned or poorly fitted lids and bases is minimized. This results in superior packaging that maintains a high level of visual appeal and structural integrity, ensuring that the final product is ready for consumer use.

5. Reduced Waste: The accuracy of the system reduces the likelihood of material wastage, as there is less chance of misalignment or defective components. By optimizing the use of materials, manufacturers can also reduce costs, contributing to a more sustainable production process.

Applications of Visual Positioning Equipment in Tian Di Gai Box Production

The application of Visual Positioning Equipment is invaluable in various industries that require high-quality packaging solutions. Tian Di Gai style boxes are often used for products such as luxury gifts, high-end cosmetics, electronics, and premium beverages. These industries demand precise, attractive packaging that not only protects the product but also enhances its appeal.

Luxury Packaging: For high-end products, a well-aligned lid and base not only ensure product safety but also enhance the perceived value of the item. Visual Positioning Equipment guarantees that each box meets the highest standards of craftsmanship.

Cosmetics and Beauty Products: Cosmetics packaging often includes intricate designs and requires perfect symmetry. Visual Positioning Equipment ensures that the patterns and designs are aligned precisely, maintaining the integrity of the branding.

Electronics Packaging: Packaging for delicate electronics requires a sturdy, well-aligned structure to protect the contents. The equipment ensures that each box is made to the exact specifications, safeguarding the product during transit.

Future of Visual Positioning in Packaging

As packaging technology continues to evolve, the integration of Visual Positioning Equipment will become more sophisticated, offering even higher levels of precision and automation. With advancements in artificial intelligence and machine learning, future systems may become capable of not just adjusting positions but also predicting and preventing misalignments before they happen.

This technology will also become increasingly integrated with other machinery in the production line, offering a more streamlined and automated approach to box making. This integration will lead to further improvements in production efficiency, product quality, and cost-effectiveness.

Conclusion

In conclusion, Visual Positioning Equipment is revolutionizing the box-making process, particularly for Rigid Box packaging. By enhancing the precision and accuracy of lid and base alignment, this technology ensures that manufacturers can deliver high-quality packaging that meets the demands of various industries. With its ability to reduce waste, improve efficiency, and increase product quality, Visual Positioning Equipment is a vital component in modern packaging production. As the packaging industry continues to evolve, this technology will play a central role in ensuring that products are delivered in packaging that is not only functional but also visually appealing and aligned to perfection.

Embracing this innovation is key for manufacturers looking to stay competitive in an increasingly demanding market. The future of packaging is undoubtedly aligned with precision—powered by Visual Positioning Equipment.