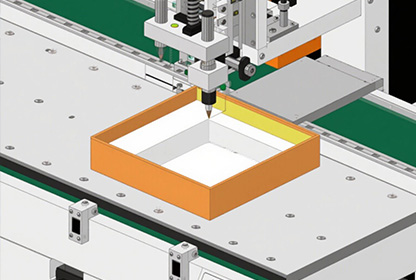

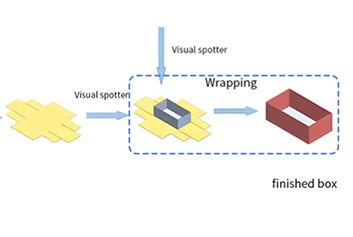

The fully automatic corner sticking machine adopts a PLC servo system and precision photosensitive eye control. The conveyor belt is stable and does not shake, and it can accurately complete the set instructions to achieve the designated position of the corner edge labeling.

1.High degree of automation: The equipment design is reasonable, with a high degree of automation, effectively reducing human involvement and avoiding label errors caused by human uncertainty. The device is equipped with a built-in corner missing sticker alarm function. Once a missing sticker is detected, it will immediately stop working and issue an alarm, avoiding the production of defective products and saving manpower and financial resources.

2.Wide applicability: The fully automatic corner sticking machine is suitable for various industries and products, such as rectangular medicine boxes in the pharmaceutical industry, data cable boxes in the electronics industry, charging head boxes, headphone boxes, etc. The labeling range of the equipment is wide, suitable for labeling the corners of small boxes of different specifications.

3.Easy debugging operation: The debugging operation is simple, and the whole machine debugging time is short, usually only 10-20 minutes are needed to complete the debugging. In addition, the equipment uses a paper drawing belt feeding structure, which ensures smooth feeding without blocking the tape, greatly improving production efficiency.

4.Multifunctionality: The fully automatic corner sticking machine is not only suitable for various industries and products, but also has functions such as secondary corner sticking and oblique edge corner sticking. The equipment uses various types of tape, such as transparent tape, PET tape, white tape, kraft paper tape, etc., to meet different production needs.

Download

Download

.jpg)

3.jpg)

2.jpg)

7.jpg)

4.jpg)

5.jpg)

9.jpg)