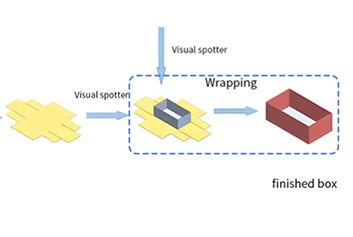

In the fast-paced modern production, packaging efficiency and quality are important aspects of enterprise competition. To meet the market's demand for efficient and precise packaging equipment, fully automatic corner sticking machines have emerged. This device, with its advanced PLC programming technology, intuitive touch screen human-machine interface, and powerful functional features, has become an ideal choice for packaging various types of sky and earth cover boxes such as mobile phone boxes, shoe boxes, mooncake boxes, jewelry boxes, shirt boxes, etc.

1. Technical highlights

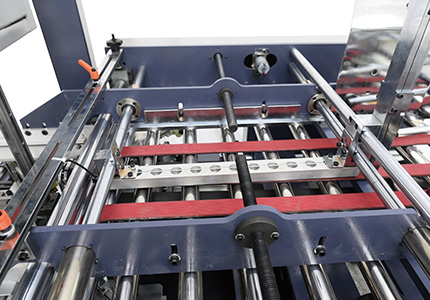

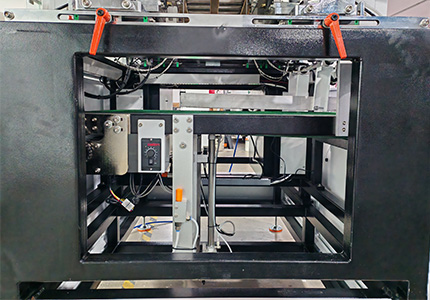

PLC programming technology: JX-TJ450 adopts advanced PLC (Programmable Logic Controller) programming technology to achieve intelligent control of equipment. Through precise programming, the device can automatically complete the entire process of applying adhesive tape to the corners according to preset parameters, ensuring that every operation is accurate and error free.

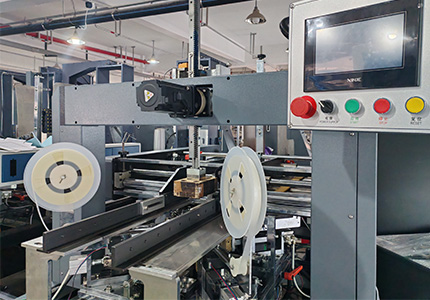

Touch screen human-machine interface: The device is equipped with an intuitive touch screen human-machine interface, allowing operators to easily set parameters, monitor status, and troubleshoot through the screen. This design not only simplifies the operation process, but also improves the usability and maintainability of the equipment.

Parameter debugging and fault display: JX-TJ450 supports parameter debugging, and operators can adjust various parameters of the equipment according to actual needs to achieve the best packaging effect. At the same time, the device also has a fault display function. Once a fault occurs, the screen will immediately display an error message to help the operator quickly locate and solve the problem.

2. Functional characteristics

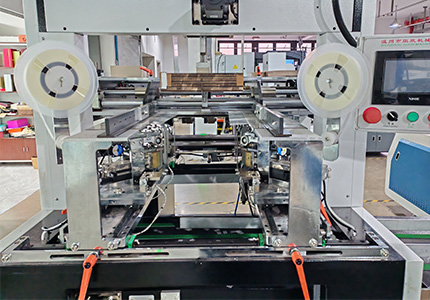

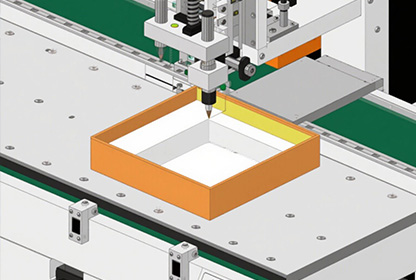

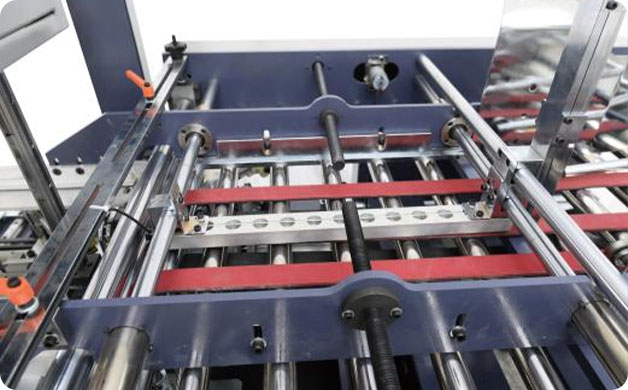

Complete the four corner adhesive tape at once: JX-TJ450 can automatically attach the tape to the four corners of the box without manual intervention, greatly improving packaging efficiency.

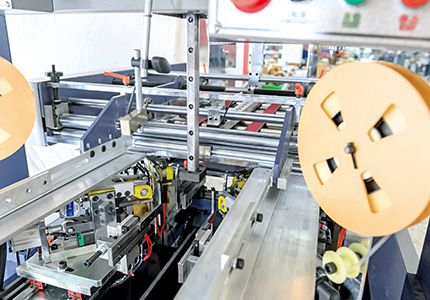

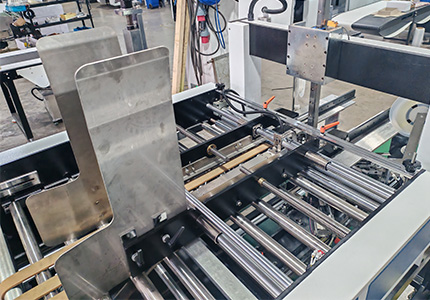

Automatic feeding and discharging: The equipment is equipped with an automatic feeding and discharging system, which achieves full automation from raw material input to finished product output, further saving labor costs.

Easy to operate and fast: The operation interface of JX-TJ450 is concise and clear, and operators only need to undergo simple training to get started. At the same time, the device runs very fast and can complete a large number of box packaging tasks in a short period of time.

Good quality: Thanks to advanced automation technology and precise debugging parameters, JX-TJ450 can ensure that every packaging meets high-quality standards. Whether it's packaging needs for high-end products such as phone boxes, shoe boxes, or jewelry boxes, they can all be perfectly met.

Download

Download