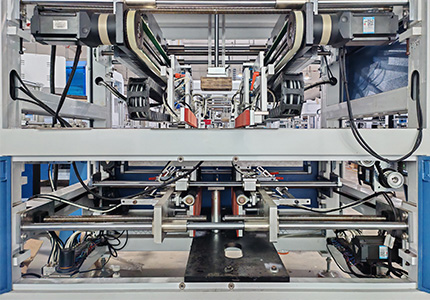

The automatic sensing arm can precisely control the operation process, achieve fast and accurate operation, reduce waiting and idle time in the production process, and significantly improve the production line's capacity. In addition, they can complete a large number of repetitive tasks within a specified time frame

PLC is made of sturdy and durable components that can operate reliably in harsh environments. They have strong resistance to electrical noise, voltage fluctuations, and temperature changes.

Convenient programming: PLCs are programmed using ladder logic language, which is similar to electrical drawings and allows programmers to easily understand and modify control logic. In addition, many PLC manufacturers offer intuitive programming software that simplifies the development process.

Strong adaptability: PLC can be easily reprogrammed to meet constantly changing control requirements. They can handle a wide range of input and output signal types, and through modular design, functional modules 1 can be added or removed as needed.

High cost-effectiveness: PLC has been highly standardized and mass-produced, thereby reducing costs. They are easy to install and maintain, reducing downtime and maintenance costs.

Space saving: PLCs adopt a compact design, which takes up less space compared to other control systems. This is particularly valuable for applications with limited space.

Easy to maintain: The PLC control system is easy to design, install, debug, and maintain, with a small maintenance workload of 34.

Powerful features: Modern PLCs provide advanced control functions such as motion control, process control, and data acquisition, meeting industry standards.

The application of programmable control systems in different industries:Methods to improve the reliability of programmable control systems:

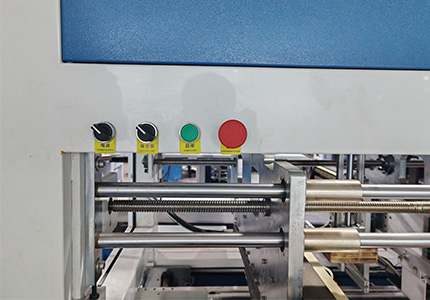

A well-designed fault alarm system: In the design of the automatic control system, a 3-level fault display system is designed to promptly detect problems and prompt operators to troubleshoot as soon as possible.

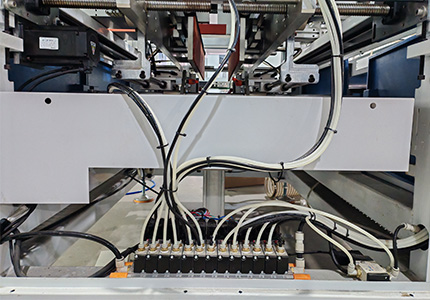

Use high-quality power supplies and input/output devices: Ensure that the power supply voltage level, frequency, and ripple factor meet the requirements, and choose high-quality input/output devices such as proximity switches, contactors, etc

Robotic arms can significantly improve work efficiency, reduce the number of manual operations and workload. Realize full automation.

The basic unit circuit structure of digital circuits is simple, allowing for significant component dispersion and facilitating large-scale integration

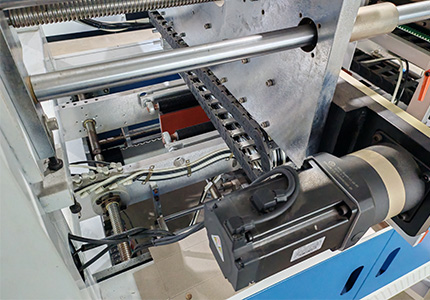

Servo motors have advantages such as high precision, fast response, strong stability, multifunctionality, and energy saving and environmental protection during the bubble pressing process, making them suitable for bubble pressing processes that require high precision and stability.

Download

Download