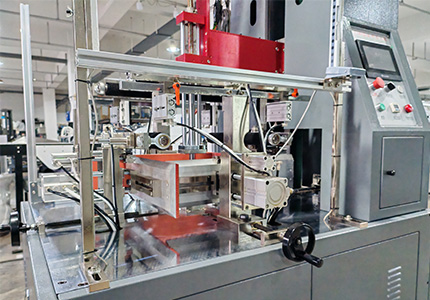

This type of machine can produce 15-25 hardcover boxes per minute, greatly improving the production efficiency of hardcover boxes and saving production costs.

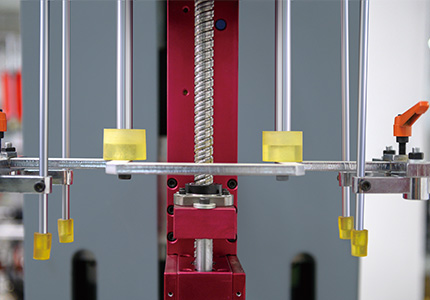

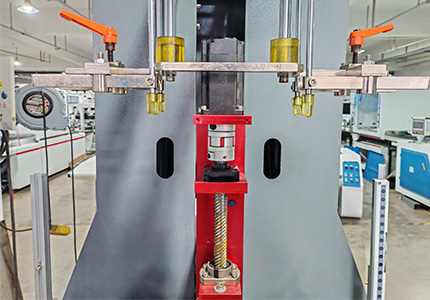

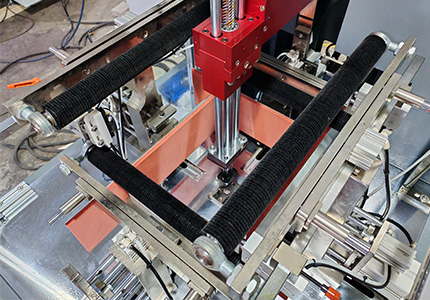

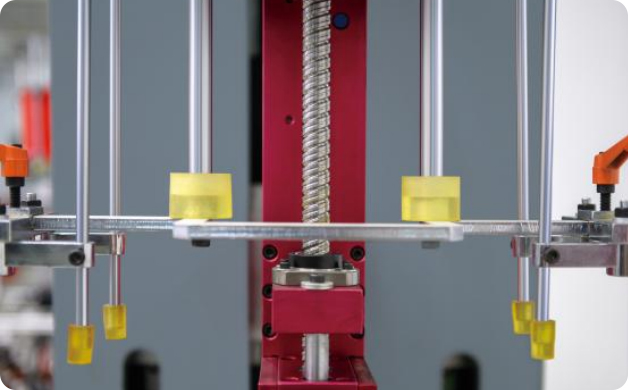

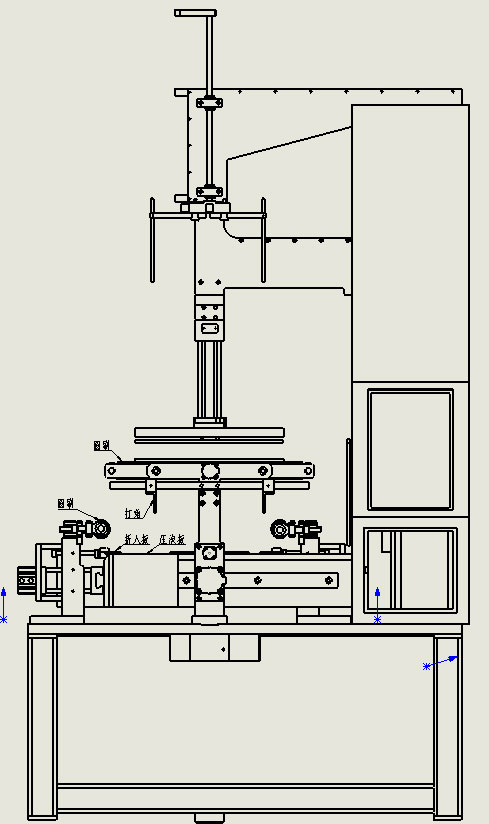

(1). The machine adopts servo pneumatic and PLC control.

(2). The machine is easy to debug through the human-machine interface.

(3). All control components of the machine are made of international high-end brands, with few faults and high precision.

(4). Machines that touch the emergency stop switch, such as pressing the automatic stop button.

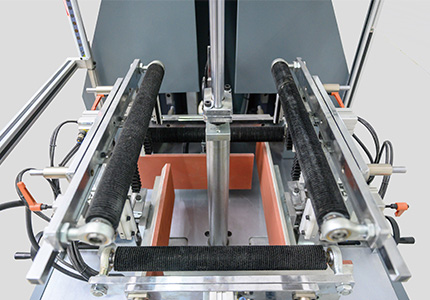

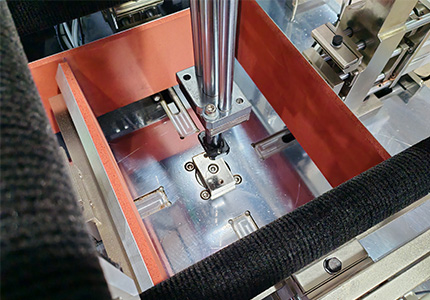

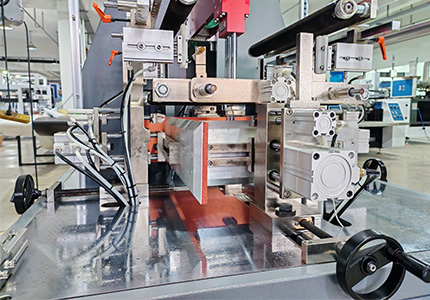

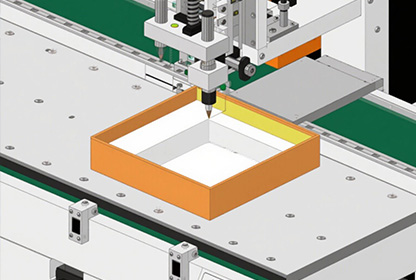

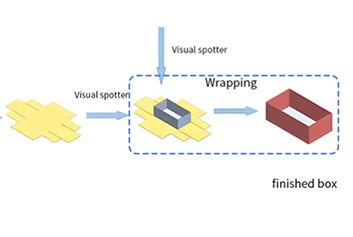

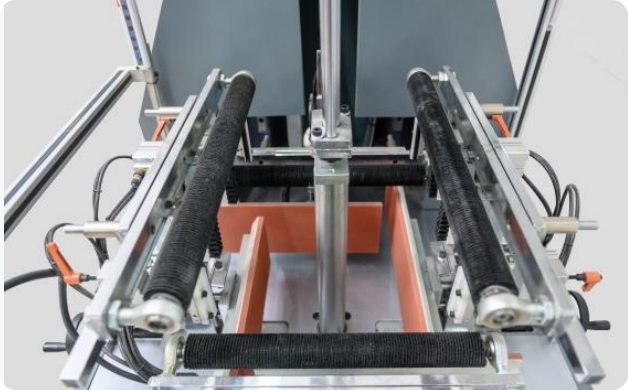

(5). The manual heaven and earth cover forming and folding machine manually positions the inner box and face paper on the assembly line, and then puts the positioned paper box onto the machine's wooden mold. The machine completes the operations of pasting, folding, and pressing bubbles on its own, and the entire process is simple and easy to implement.

(6). Due to the mechanical completion of each action and standardized production of the product, the quality of the product has been greatly improved.

(7). The whole machine is fully controlled by pneumatic control, with a simple and reasonable structure. Debugging is completed through a human-machine interface selection method, which is simple and easy to adjust.

(8) Low failure rate: All control components adopt high-end national standard brands, with low failure rate and high precision. If there is a malfunction in the machine, it will be directly displayed on the screen for easy troubleshooting.

(9) This type of machine can produce 15-25 hardcover boxes per minute, greatly improving the production efficiency of hardcover boxes and saving production costs.

Product Details

Durable and sturdy: Made of high-quality materials, it has high durability and reliability, and can work stably in various environments.

Quick response: With a fast response time, it can quickly respond to user operations and provide a smooth user experience.

Multifunctionality: It has multiple functions, such as supporting multiple data transmission interfaces, built-in memory, etc., which can meet different data transmission and storage needs.

High cost-effectiveness: Compared to other brands' touch screens, it has a price advantage and high cost-effectiveness, making it suitable for users with limited budgets.

Wide application scenarios: Suitable for various application scenarios, such as industrial automation, monitoring systems, etc., with a wide range of market applications.

Technical support: Provide rich technical support and programming software to facilitate user development and debugging.

Download

Download