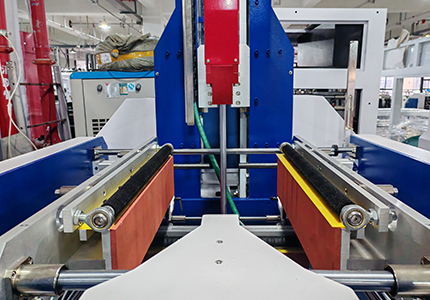

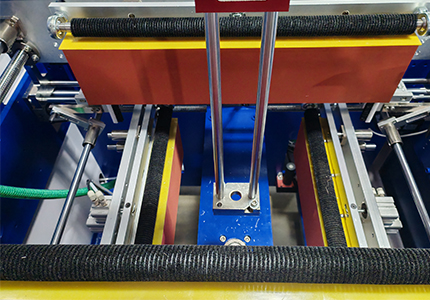

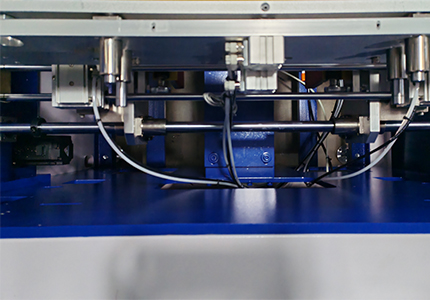

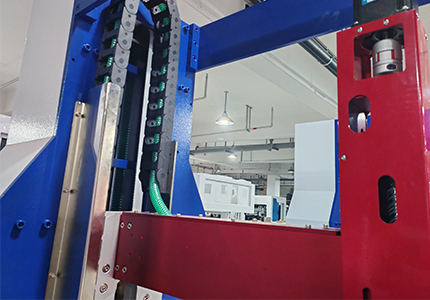

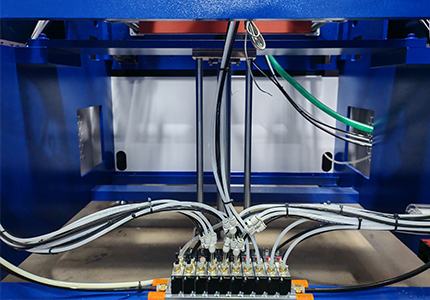

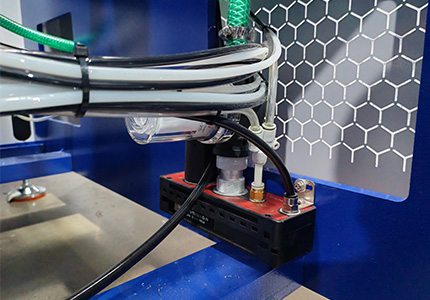

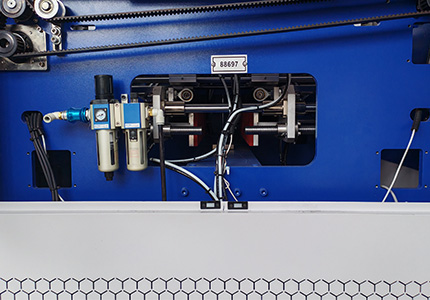

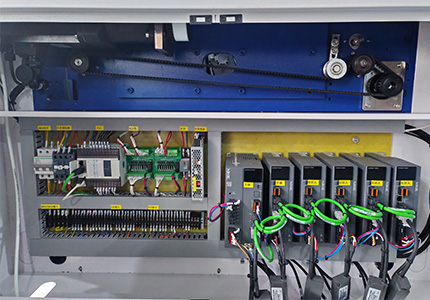

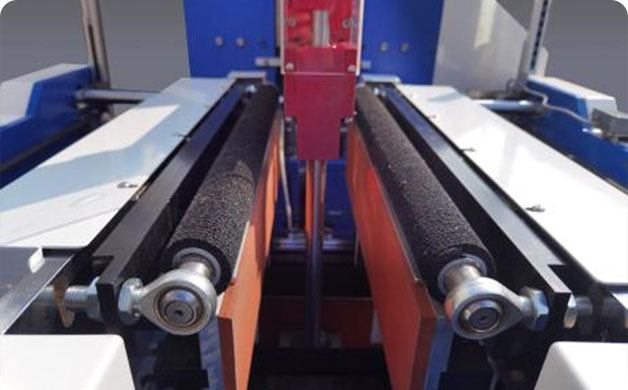

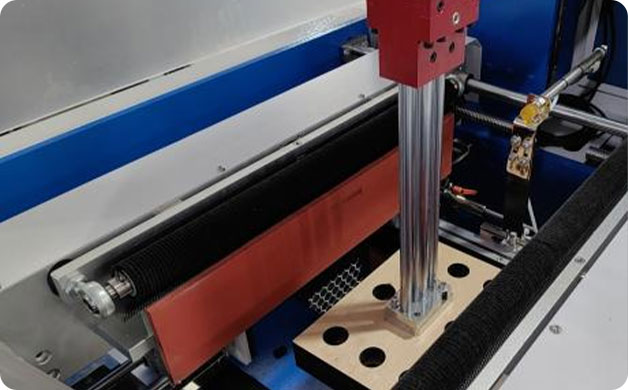

The equipment uses servo motors to provide power and achieves precise control of various actions through pneumatic technology. Servo motors have the characteristics of high precision, high stability, and high response speed, ensuring the stable operation and precise control of the equipment.

Servo motor and pneumatic technology: The equipment uses servo motors to provide power and achieves precise control of various actions through pneumatic technology. Servo motors have the characteristics of high precision, high stability, and high response speed, ensuring the stable operation and precise control of the equipment.

PLC programming control: The control system of the equipment adopts PLC programming control, which can achieve precise control and coordination of various actions. PLC has the advantages of high reliability, flexible programming, easy maintenance and expansion, providing strong guarantee for the stable operation of equipment.

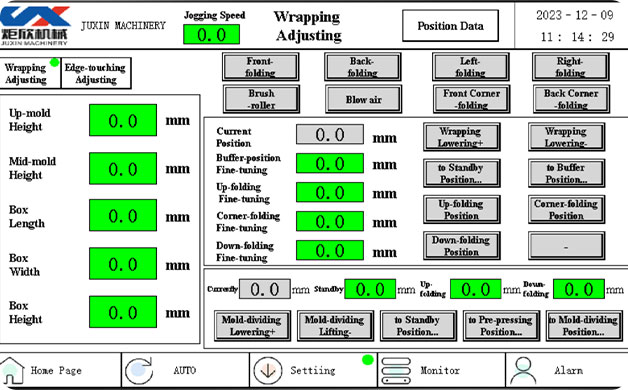

Human machine interface: The device is equipped with a human machine interface, allowing operators to select debugging parameters and monitor the device's operating status through the interface. The human-machine interface has the characteristics of being intuitive and easy to operate, greatly reducing the difficulty of operation and debugging time.

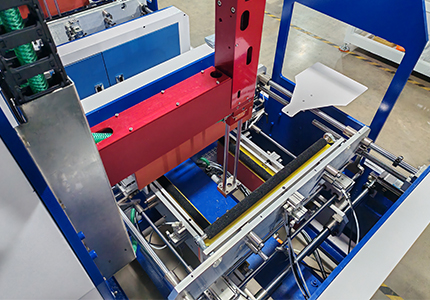

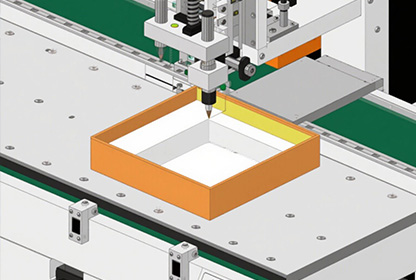

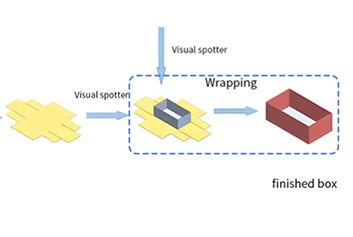

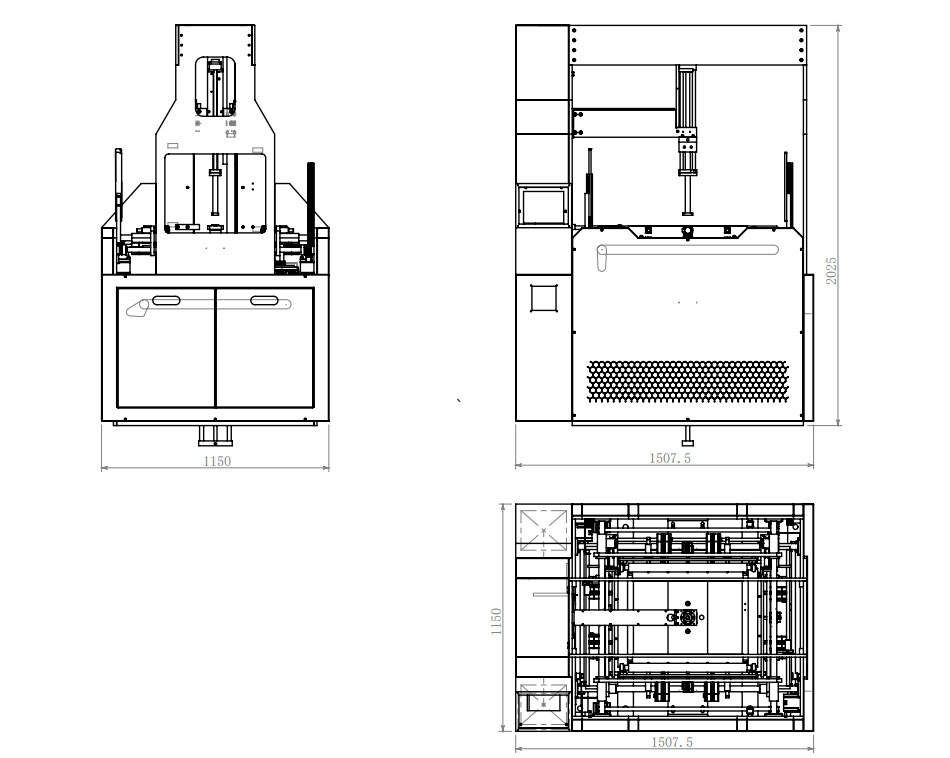

This equipment is an ideal automation device for producing gift boxes and hard boxes. It combines advanced servo motor and pneumatic technology, and achieves automation of a series of actions such as loading, folding, and forming through PLC programming control. By manually positioning the inner box and dough on the assembly line, placing the fixed box into the machine's wooden mold, the equipment can automatically operate, greatly improving production efficiency.

Efficient production: 15-20 boxes can be produced per minute, greatly improving production efficiency compared to traditional manual production methods.

Cost savings: Due to the use of standardized mechanical defense products in the production of the equipment, every action is precisely controlled, greatly reducing production costs.

Improving quality: The automated production of equipment ensures that the size, shape, and appearance of each box meet uniform standards, thereby improving the quality of the product.

Flexible debugging: The debugging of the equipment is completed by selecting the human-machine interface, which is easy to operate and adjust, and can be quickly adjusted according to different production needs.

Download

Download